Engineered Products

Industrial

Industrial Silencers

Upper Transition

Upper Transition

Placing Lower Transition

Placing Lower Transition

Lower Transition in Place

Finished Stack

Finished Stack Painted

5G and 6G Finished Stacks

Industrial Silencers

Light Industrial Silencers

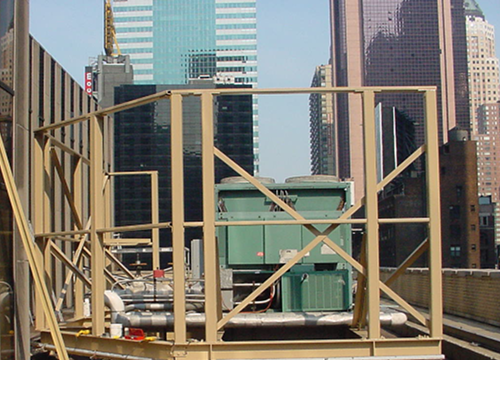

Rooftop Silencers

Rooftop Silencers

A fan radiates noise equally through its inlet and its discharge. Usually either the inlet or outlet of the fan is connected to some sort of equipment which contains and/or absorbs the noise from that side of the fan. Normally only the inlet or discharge has to be silenced. One exception is that type of air conditioning systems in which both the inlet and the discharge are ducted into occupied spaces. In these installations silencers are often required on both the inlet and discharge sides of the fan.

A fan radiates noise equally through its inlet and its discharge. Usually either the inlet or outlet of the fan is connected to some sort of equipment which contains and/or absorbs the noise from that side of the fan. Normally only the inlet or discharge has to be silenced. One exception is that type of air conditioning systems in which both the inlet and the discharge are ducted into occupied spaces. In these installations silencers are often required on both the inlet and discharge sides of the fan.

Light Industrial Silencers

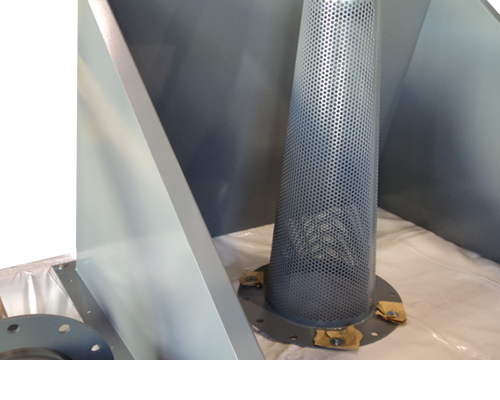

Inlet Filter Systems

Inlet Filter Systems

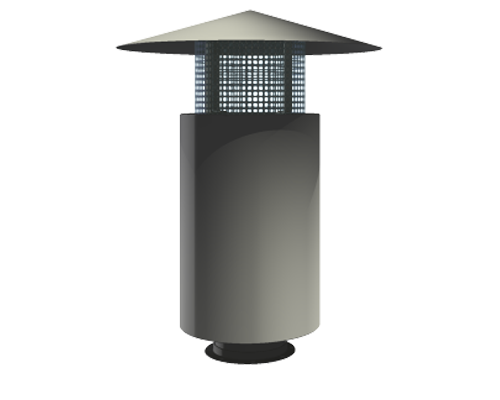

Stack Silencers

Stack Silencer

Stack

Stack without Silencer

Stack with Silencer

2500 ft. Measurement

5 Mile Measurement

Stack without Silencer

Stack without Silencer

Stack with Silencer

Stack with Silencer

Stack with Silencer

Stack Silencers

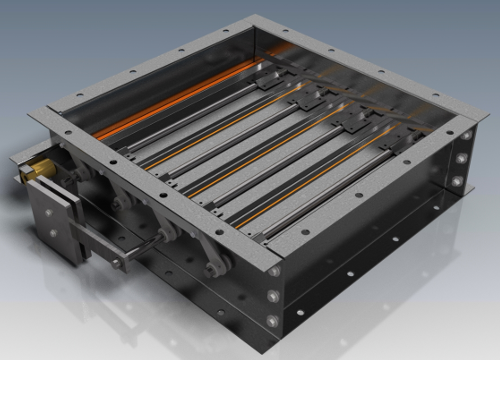

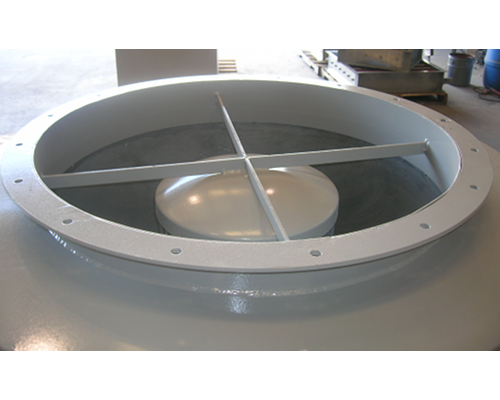

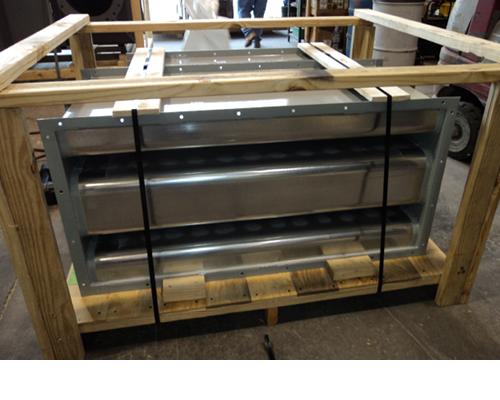

Dampers Manual & Actuated

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

The Aeroacoustic Corporation offers a line of Industrial Dampers. Select from 3 styles: Volume Control, Backdraft and CO2 Trip Dampers and customize their sizes to suit your application.

Dampers Manual & Actuated

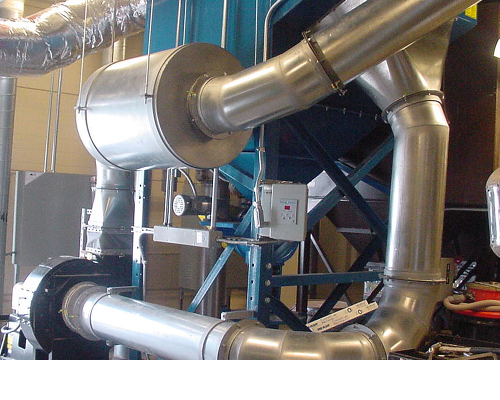

Ductwork

Ductwork

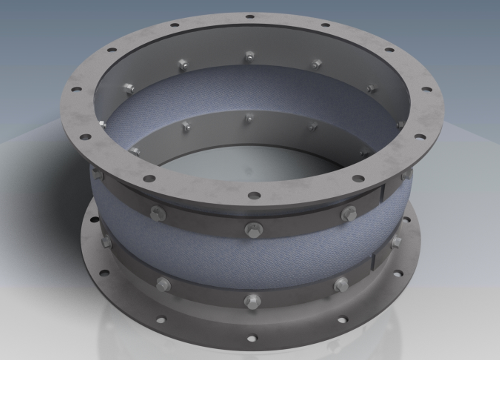

Flex Connector

Flex Connector

Ancillary Equipment

Turning Vanes

Turning Vanes

Airport Artistic Suspended Fixtures

Foam Lagging

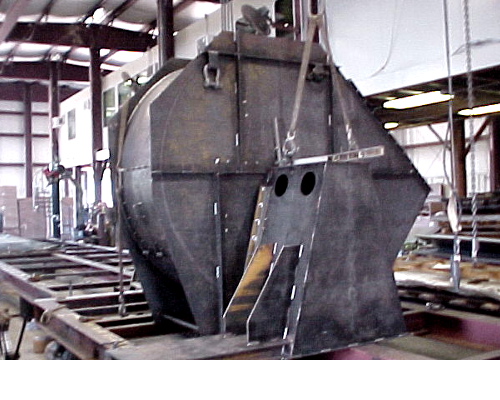

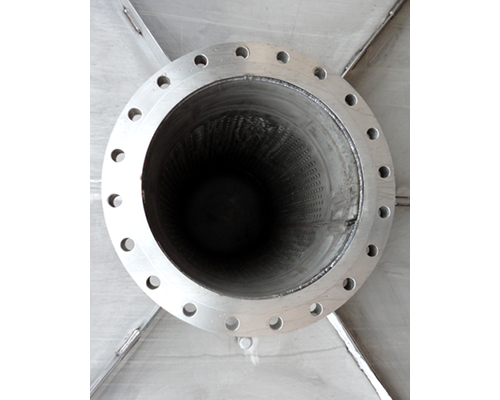

Supersonic Tunnel Diffuser

Fan Housing with Unitary Base

Fan Housing with Unitary Base

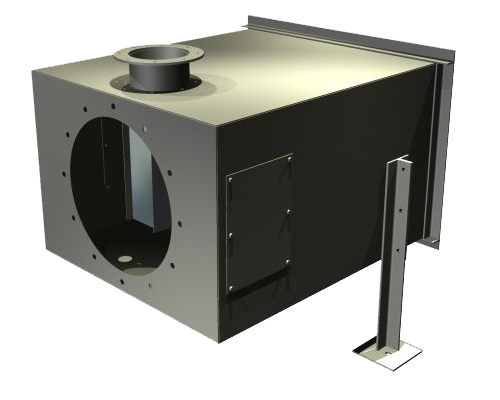

Fan Housing with Inlet Box

Fan Housing with Inlet Box

Fan Housing with Inlet Box

Fan Housing with Motor Base

Ancillary Equipment

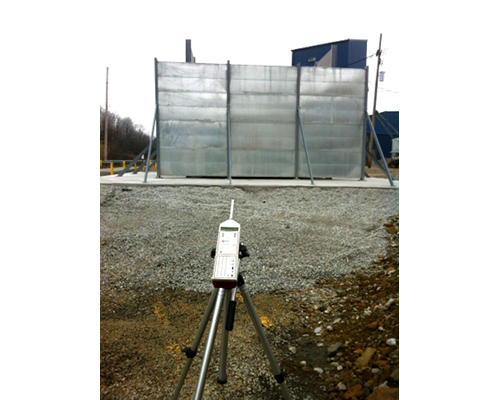

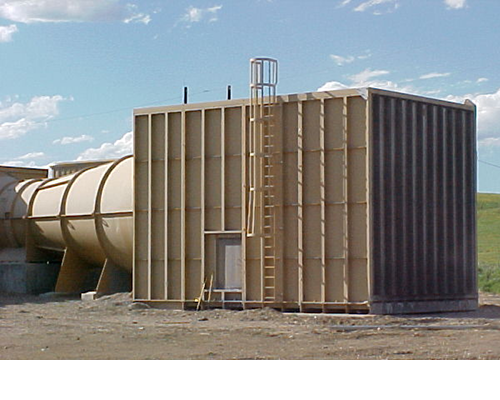

Acoustical Barriers

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Be it a rural or urban setting, noisy equipment is an issue. You may need to meet a noise ordinance, regulation or just want to be a good neighbor. The use of an acoustical barrier is an effective solution to reduce the noise level at the receiver without interfering with equipment operation. Here at The Aeroacoustic Corporation we have an engineered solution to meet your requirements.

Acoustical Barriers

Acoustical Enclosures

Acoustical Enclosures

Acoustical Panels

Acoustical Panels

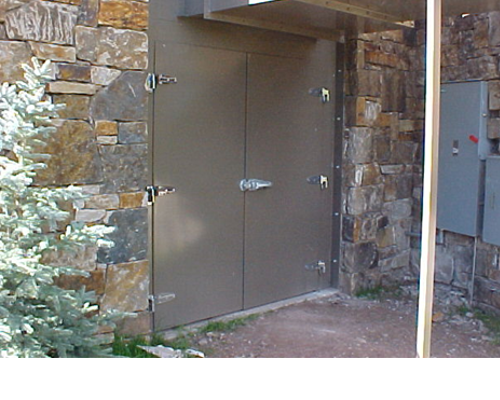

Acoustical Doors

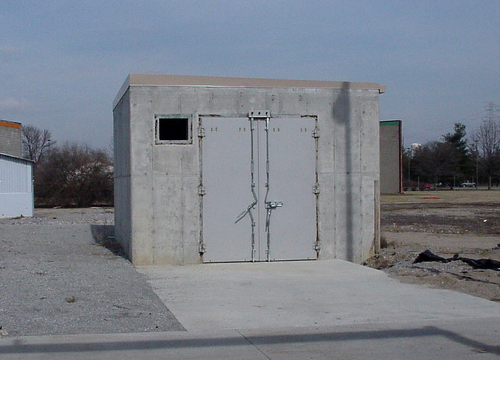

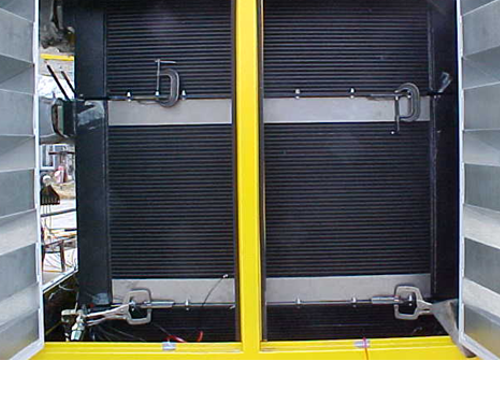

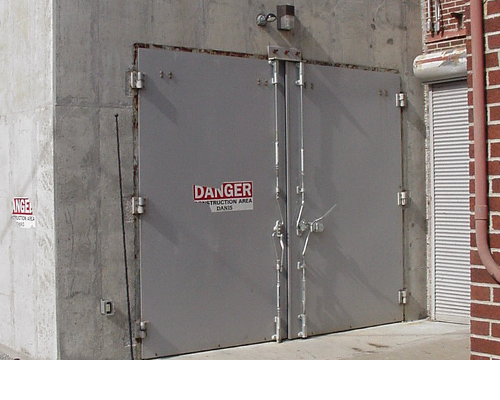

Blast Doors

Blast Doors

Blast Doors

Blast Doors

Test Cell Door

Sound Door

These heavy steel plate Jet Engine/Turbine Blast Doors are available in a variety of sizes and configurations: single hinge, double hinge, four point locking arrangement with sound proof drop bladder, bottom seals eliminate the need for a sill plate for smooth forklift entrance and egress. Locking assemblies are mounted outside the door for ease of maintenance and adjustment. Self-Lubricated Strap Hinges are standard, and Continuous Hinges are available for special applications. Impact resistant double pane windows are available upon customer request.

These heavy steel plate Jet Engine/Turbine Blast Doors are available in a variety of sizes and configurations: single hinge, double hinge, four point locking arrangement with sound proof drop bladder, bottom seals eliminate the need for a sill plate for smooth forklift entrance and egress. Locking assemblies are mounted outside the door for ease of maintenance and adjustment. Self-Lubricated Strap Hinges are standard, and Continuous Hinges are available for special applications. Impact resistant double pane windows are available upon customer request.

These heavy steel plate Jet Engine/Turbine Blast Doors are available in a variety of sizes and configurations: single hinge, double hinge, four point locking arrangement with sound proof drop bladder, bottom seals eliminate the need for a sill plate for smooth forklift entrance and egress. Locking assemblies are mounted outside the door for ease of maintenance and adjustment. Self-Lubricated Strap Hinges are standard, and Continuous Hinges are available for special applications. Impact resistant double pane windows are available upon customer request.

These heavy steel plate Jet Engine/Turbine Blast Doors are available in a variety of sizes and configurations: single hinge, double hinge, four point locking arrangement with sound proof drop bladder, bottom seals eliminate the need for a sill plate for smooth forklift entrance and egress. Locking assemblies are mounted outside the door for ease of maintenance and adjustment. Self-Lubricated Strap Hinges are standard, and Continuous Hinges are available for special applications. Impact resistant double pane windows are available upon customer request.

These heavy steel plate Jet Engine/Turbine Blast Doors are available in a variety of sizes and configurations: single hinge, double hinge, four point locking arrangement with sound proof drop bladder, bottom seals eliminate the need for a sill plate for smooth forklift entrance and egress. Locking assemblies are mounted outside the door for ease of maintenance and adjustment. Self-Lubricated Strap Hinges are standard, and Continuous Hinges are available for special applications. Impact resistant double pane windows are available upon customer request.

This series of single and double acoustic doors comes with pre-fitted door bucks in a variety of thicknesses and configurations. Accessories include panic bars, locking devices, alarms and sound proof windows.

Acoustical Doors

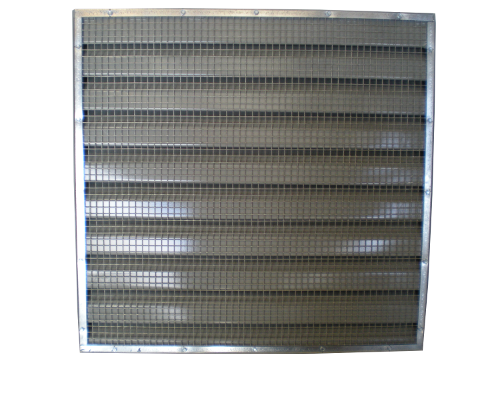

Acoustical Louvers

Swing-Away Equipment Doors (Closed)

Swing-Away Equipment Doors (Opened)

Acoustical Louver (Front)

Acoustical Louver (Back)

Engine Room Door for the U.S. Coast Guard

These acoustic louvers provide the maximum noise reduction obtainable in a short depth while still giving an effective combination of privacy and weather protection. Designed for a variety of applications, they are used in installations such as process air intakes, fresh air intakes for ventilation systems, mechanical equipment screens, cooling tower inlets, etc.

These acoustic louvers provide the maximum noise reduction obtainable in a short depth while still giving an effective combination of privacy and weather protection. Designed for a variety of applications, they are used in installations such as process air intakes, fresh air intakes for ventilation systems, mechanical equipment screens, cooling tower inlets, etc.

These acoustic louvers provide the maximum noise reduction obtainable in a short depth while still giving an effective combination of privacy and weather protection. Designed for a variety of applications, they are used in installations such as process air intakes, fresh air intakes for ventilation systems, mechanical equipment screens, cooling tower inlets, etc.

These acoustic louvers provide the maximum noise reduction obtainable in a short depth while still giving an effective combination of privacy and weather protection. Designed for a variety of applications, they are used in installations such as process air intakes, fresh air intakes for ventilation systems, mechanical equipment screens, cooling tower inlets, etc.

The above shown acoustic louver doors swing in so that they do not obstruct corridor traffic. They help allow the engine room to breath freely and significantly reduce excessive sound energy into personnel corridor. This series of acoustic louver doors are completely at home in a wet wash down environment.

Acoustical Louvers

Fan Silencers

Rectangular Splitter Silencer

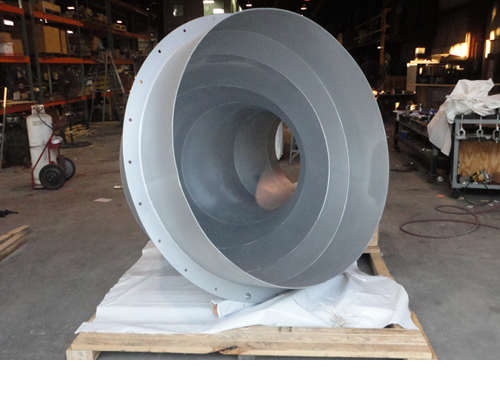

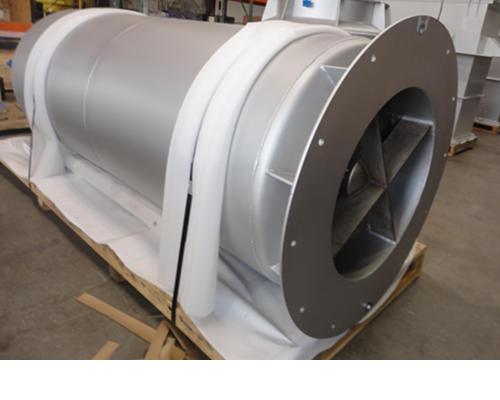

Circular Splitter Silencer

Model IB Inlet Box Silencers

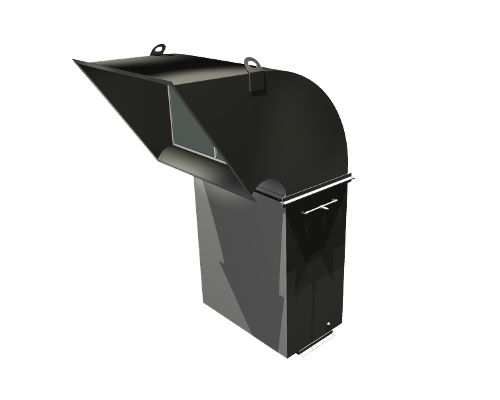

Model DF Discharge Silencers

Model CI Circular Inlet Silencers

Model SI Side Inlet Silencers

Tubular Silencers

The "Silentflow" Model IB inlet silencer features an internal configuration designed so that the silencer exit matches the fan inlet box. The silencer's discharge flange is customized to fit the fan's inlet box bolt pattern, eliminating the need for a separate transition piece. A 1" x 1" galvanized mesh inlet screen is included at no additional cost.

The "Silentflow" Model DF discharge silencer is designed to be used when the fan inlet is connected to the process but discharges to atmosphere. The required silencer is generally larger than the fan discharge connection, in which case a transition may be purchased to connect the silencer to the fan.

"Silentflow" Model CI inlet silencer is designed to bolt directly to the fan inlet flange. The silencer includes a silencing section followed by a plenum section with one or two access doors for installation and inspection. A 1" x 1" galvanized mesh inlet screen is included at no additional cost.

The "Silentflow" Model SI inlet silencer is designed to bolt directly to the fan inlet flange. The silencer includes a silencing section followed by a plenum section large enough to accommodate the fan inlet opening. One or two access doors are incorporated into the back of the plenum for installation and inspection. A 1" x 1" galvanized mesh inlet screen is included at no additional cost.

The "Silentflow" Tubular silencer is used where noise reduction is needed combined with a very low pressure drop. It is designed to bolt directly to the fan, but can be combined with a round-to-round transition to allow the fan to attach to larger tubular silencers. Where necessary, certain models of the Tubular silencer are outfitted with centerbodies to further improve performance of sound attenuation.

Fan Silencers

Chiller Acoustic Treatment

Before Treatment

Before Treatment

Before Treatment

After Treatment

After Treatment

After Treatment

Chiller Acoustic Treatment

Coal Mine Silencers

Typical Mine Shaft

Coal Mine Silencers

Tubular Silencers

Tubular Silencers

Tunnel Silencers

Tunnel Silencers

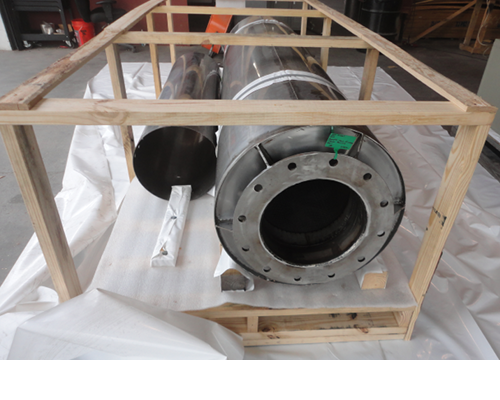

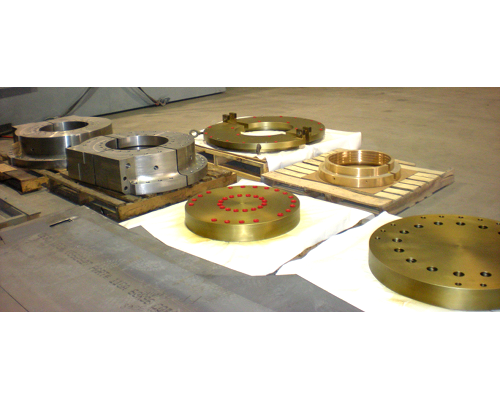

Machining

Machining

Shipping Methods

Shipping Methods

Industrial

Jet Engine Test Cell

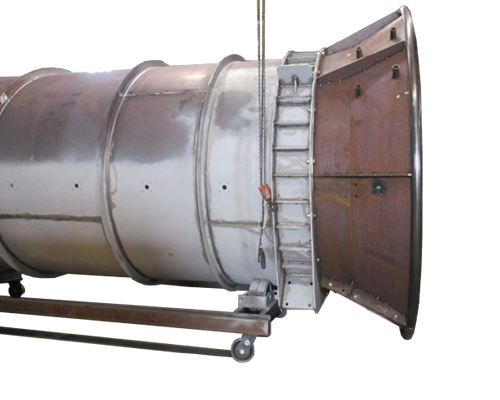

Augmenter

Augmenter

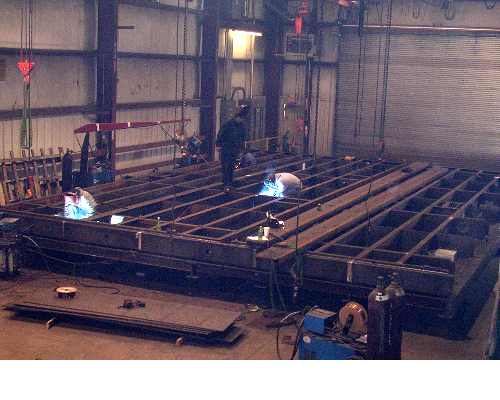

Diffusers & Support

Diffuser

Test Cell Diffuser Support

Test Cell Diffuser Support

Diffusers & Support

Wall Panel Systems

Wall Panel Systems

Blast Doors

Blast Doors

Main Access Doors

Main Access Doors

Jet Engine Test Cell

Power

Vent and Blow-Off Silencers

Vent and Blow-Off Silencers

Exhaust Silencers

Exhaust Silencers

Gas Turbine Exhaust

Install Transition

Install Transition

Attach Empty Chamber

Fill Chambers

Fill Chambers

Fill Chambers

Final Stage

Final Stage

Finishing Touches

Gas Turbine Exhaust

Tubular Exhaust Silencers

Tubular Exhaust Silencers

Intake Plenums

Intake Plenums

Power

Non-Acoustical

Design, Engineering & Manufacturing of:

- Steam Boiler Blowoff Silencers

- Gas and Steam Turbine Enclosures and Silencers

- Diesel Generator Enclosures and Sound Rooms

- Fan Silencers

- Piezometer Tubes

- (See more...)

- Air Filters and Accessories

- Acoustic Weather-proof Louvers

- Compressor Enclosures and Portable Personnel Rooms

- Acoustic Control Rooms

- Noisy Chimney Stack Stuffers

- Sound Proof Impact Resistant Doors

- Sound Proof Impact Resistant Windows

- Electric Motor Silencers

- Coal Mine Ventilating Shaft Silencers

- Sound Walls and Highway Barriers

- Jet Engine Test Cell Acoustic Treatment and Augmenters

- Industrial and Commercial Air-Conditioning Equipment and Duct Treatment

- Water Cooling Tower Treatment

- (See less...)

- Available Upon Request

- Fan Silencer Design Software

- Technical Catalogs

- Certified Welding Procedures

- Quality Control Procedure Manuals